A Closer Look at the Difference

In short: Zotefoams are unlike any other foam, Azote foams are engineered to offer superior performance. Produced using a unique autoclave process, the Azote range includes world-leading technical foam brands Plastazote and Evazote.

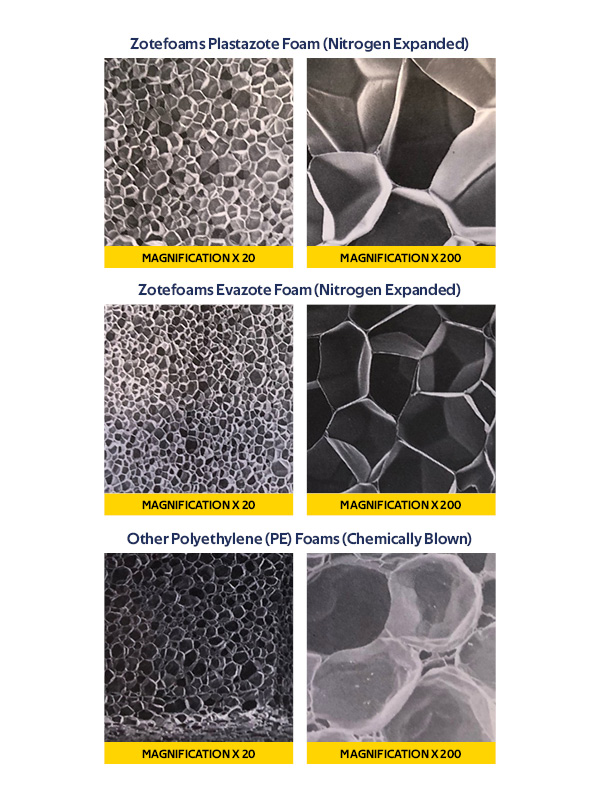

To the human eye like a luxury high quality foam but if we look closer with a microscope the foam’s benefits become clear. Zotefoams Plastazote and Evazote foams have extremely consistent cell size and the cell’s shape and structure is much stronger than other foams.

You can see this in the graphic supplied.

Strongest Under Stress

Because of the highly Uniform, Crosslinked Cells, only possible using Zotefoam’s patented nitrogen expansion process, Plastazote and Evazote foams perform stronger than other comparable foams in all mechanical, energy absorption, chemical and thermal tests.

Let’s use some test data from Plastazote LD29, a Polyethene (PE) foam with a density of 29kg/m3.

To compress the Zotefoams Plastazote LD29 a standardised amount it required 63kPa (9psi) a significate increase in strength compared to the closest competitor at 48kPa (7psi). Plastazote LD29 an already lighter weight closed cell foam showing great performance.

Comparable Foam = 48kPa (7psi)

Plastazote LD29 = 63kPa (9psi)

Exceptional Purity

A pure foam like no other, No micro-breaks or dust particles come from the foam as its strength and resilience to breaks on a molecular level is amazing.

This means chemical and transit and long-term storage protection for medical, healthcare and even archival goods. This feature also reduces skin irritation for sports padding and therapeutic devices.

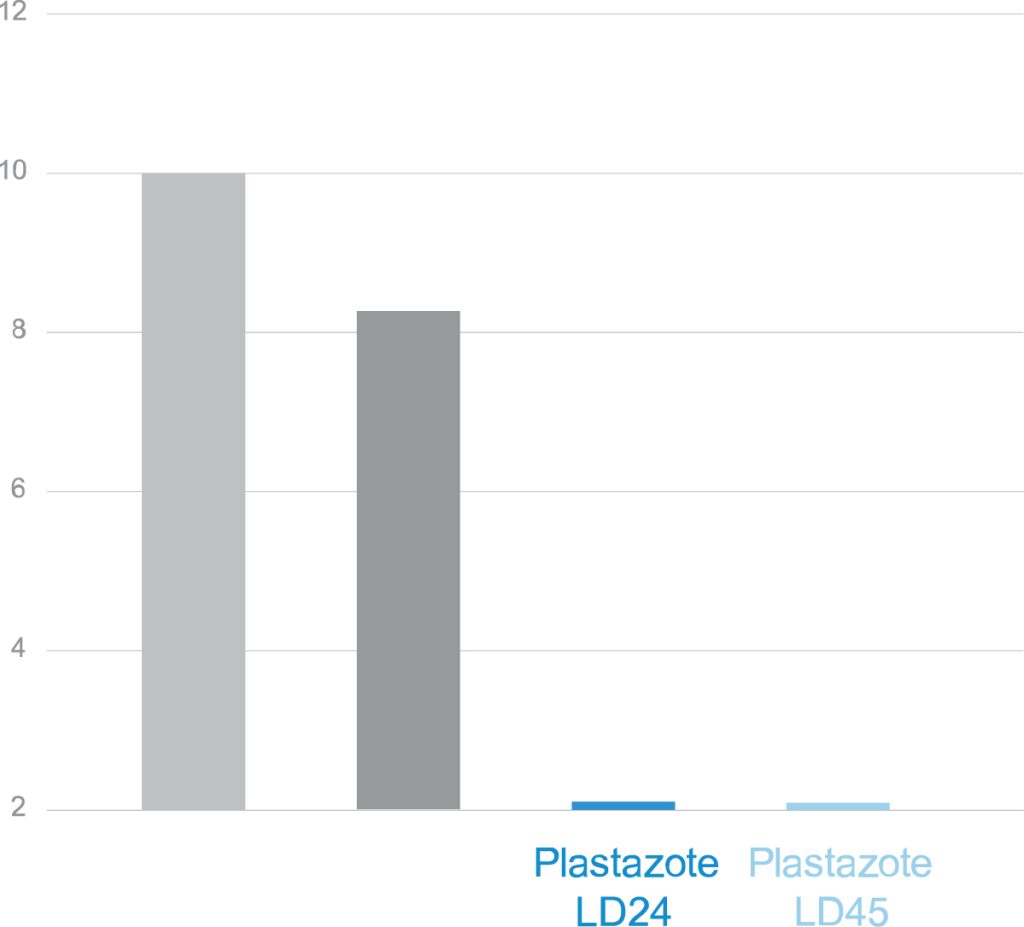

This graph shows the amount of chemical residues (%wt) detected during testing of two common, comparable polyethylene foams versus two densities of Azote Plastazote.

As shown in the graph you can see that Plastazote’s loose particles in testing is so low that competing closed cell foams have 300% more impurity under test conditions.

High purity and no solvents for low odour & toxicity, ideal for medical and wearable applications and high value archival storage and artwork transit.

Consistent Density

Uniform, Consistent Closed Cell Size and Structure.

No Irregular Points of Weakness.

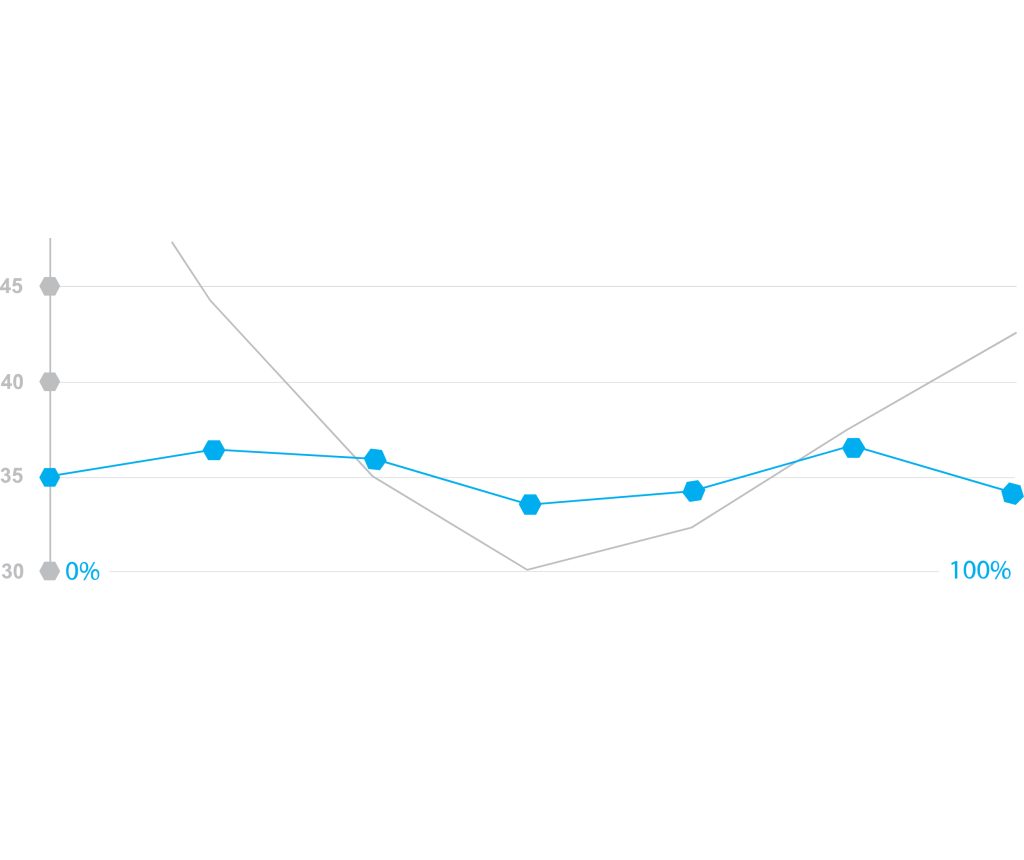

Graph shows variations of density at intervals throughout a sheet of Azote Plastazote (Compared to a similar comparative foam)

Shape Retention

Excellent retention of shape over time and frequent usage.

Unmatched packaging aesthetics and achieves robust routed edges.

What Is Zotefoams Used For?

Aviation

Azote foams are the purest and lightest materials perfectly suited to aviation and aerospace with flame retardant, conductive and static dissipative features available. Azote Plastazote is up to 70% lighter than comparable materials, resulting in weight reduction through reduced material content.

Healthcare and Medical

Plastazote (a Zotefoams product) is acknowledged as the most cited thermoplastic material in medical literature.

- Ankle, knee, back and cervical collar pads

- Patient pads for medical diagnostic and therapeutic devices

- Wearable vital signs monitoring patches

- Orthotic components

- MRI, CT and x-ray devices

- Patient positioning pads

- Wheelchair seating and positioning pads

- Medical protective helmet liners

- Prosthetic components

- Podiatric components

- Plastazote is non-absorbent, inert, is easily cleaned in warm water and provides the softest feel for gentle skin contact as well as consistently high quality results in ergonomic thermoforming.

Product Packaging

Azote foams are highly energy absorbent, lightweight, UV stable, flexible, durable and resistant to chemicals and moisture making them ideal for protection of goods in the Defence, electronics, medical and transport sectors.

Approved for military use as explosive compatible storage, Azote foams also provide conductive and static dissipative options to help reduce the occurrence of ESD damage in electronic packaging.

Personal Protection

Zotefoams Azote foams provide the softness and feel of a low density foam with the performance and strength of a high density foam making them perfect for use in personal protection.

Provide outstanding cushioning and impact absorption when used in personal protection equipment Azote is well suited for use in Defence, law enforcement and sporting applications such as body armour, gloves, helmet liners as well as knee and shoulder pads.